- Home

- All Products

- AnyScan 30/36 - Flaw Detector

AnyScan 30/36 - Flaw Detector

Ultrasonic Non-Destructive Testing employs ultrasonic waves transmitted into a test component to search for sub-surface defects. UT can be utilised on many different materials such as steel, plastics, ceramics and composites. The types of defect that can be found include discontinuities, porosity, slag, inclusions and cavities.

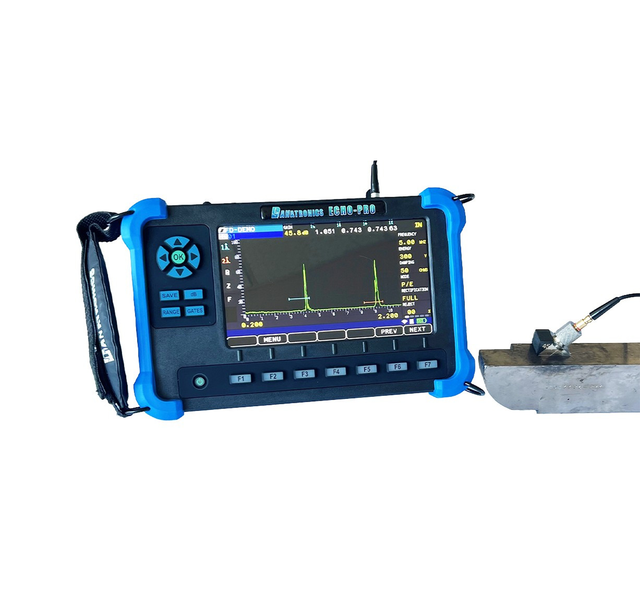

The Anyscan-30 Flaw Detector is an easy to use yet powerful and reliable instrument that can determine defects in a variety of materials allowing rapid assessment, diagnosis and reporting. An Anyscan-30 is ideal for use in Flaw Detection and Quality control applications.

Careful thought was applied to keystroke use and menu options. Regularly used functions are allocated specific keys. Multiple on-board reporting tools and a comprehensive data filing system enable you to easily collect and report high quality inspection data.

Anyscan-30 is equipped with lithium batteries with an operation time of more than 8 hours. This makes the Anyscan-30 a perfect choice for on-site testing for either novice or experienced inspectors.

Features

The Anyscan-30 unit includes a full set of shear wave probes, compression probe and cables as standard providing exceptional value in today’s competitive market.

- 400 MHz real-time hardware sampling, high-fidelity echo pulse

- Low noise broadband & amplifying circuits with selectable damping.

- Standard dynamic DAC/TCG and onboard DGS/AVG.

- Designed to meet the requirements of EN12668-1.

- Intuitive keys location and menus, creating easy operation.

- Weld Graph Displaying Function with on screen representation.

- Continuously Storing and Replaying Function playback capability.

- Excellent EMI design, good EMC performance.

- 5.7〞high resolution color LCD display.

-

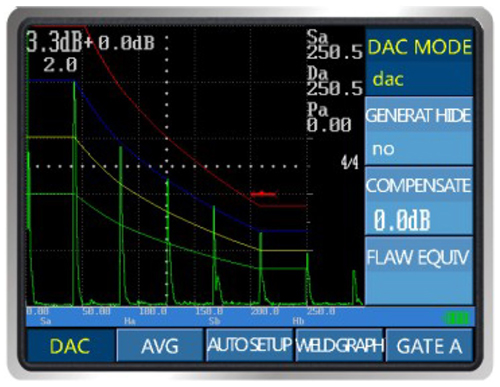

DAC file, Store and Recall

A quick and easy operation - When connecting sample points one by one, it will automatically draw four lines such as “Assess Line”, “RATINE Line”, “GENERATRIX Line” and “Void Line”. Easy to convert to different worldwide standards by dynamically adding sample points and adjusting curve offset accordingly.- DAC file, Store and Recall

- AVG Make, Store and Recall

- Envelope

- Weld Graph Display

- RF Display

- Curve Surface Amending

- Peak Hold

- Automatic Echo Spectrum Test

- Auto Gain Adjustment

- Intelligent Calibration Procedures

- Quick Channel Setup

- Automatic Report Generation

- Dynamic Waveform Store and Recall

- Waveform Zoom

- Gate Zoom

Specifications

| Specification | Value |

| Horizontal Linearity Error | ≤ 0.1% |

| Vertical Linearity Error | ≤ 3% |

| Surplus Sensitivity | ≥ 62dB |

| Dynamic Range | ≥ 40dB |

| Electronic Noise Level | ≤ 20% |

| Far-field Resolution | ≥ 30dB |

| Working Mode | Single-probe or Dual-probes |

| Transmit Pulse | 400 V negative spikes |

| Working Frequency Range | 0.5 MHz ~ 20 MHz |

| Detection Range | 0.5 mm ~ 999 mm (steel; longitudinal wave) Adjustable continuously, switch-able steps |

| Pulse Repetition Frequency | 1000 / 250 / 40 Hz |

| Sample Rate | 400 MHz hardware real-time sampling |

| Velocity | 1000 m/s ~ 15000 m/s Adjustable continuously, switch-able steps |

| Display Delay | -10 mm ~ 1000 mm Adjustable continuously, switch-able steps |

| Probe Delay | 0 μs ~ 199.9 μs |

| Damping | 50 / 100 / 200 / 500 Ω |

| Gain Adjustment | 0dB~110dB Step by 0.0/0.1/0.5/1.0/2.0/6.0dB |

| Rectification Modes | Full wave / Positive / Negative / RF |

| Display Screen | 5.7" high brightness TFT colour LCD screen 640×480 pixels |

| Measurement Mode | Flank or Peak |

| Storage and Datalogging | Commonly-used detection parameters Test result data |

| Alarm | Hardware alarms with sound and light alarm models including positive mode, negative mode and DAC mode |

| Communication Interfaces | USB, Ethernet |

| Operating Temperature | -10 ~ +50 ℃ |

| Battery | Lithium battery (10.8V 5200mAh) |

| Run Time | > 6 hours |

| Power Supply | AC: 100-240 V DC: 15 V 4A |

| Weight | ≈ 1.4Kg w. battery |

| IP Rating | IP54 |

.jpg)