- Home

- All Products

- HWT-Pro™

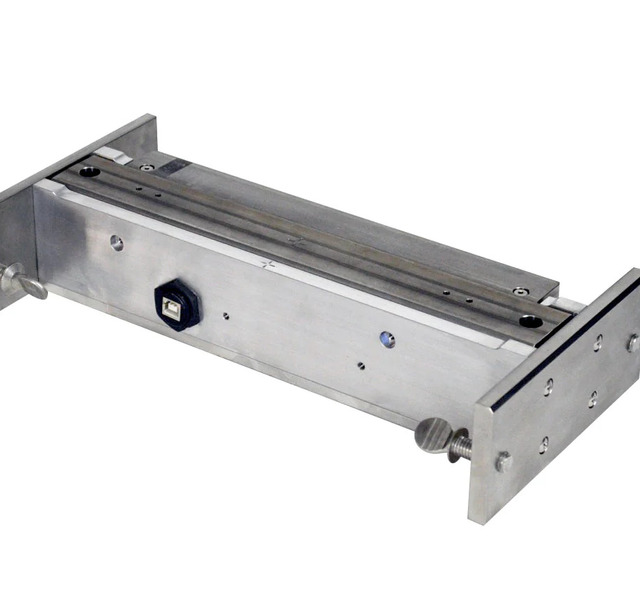

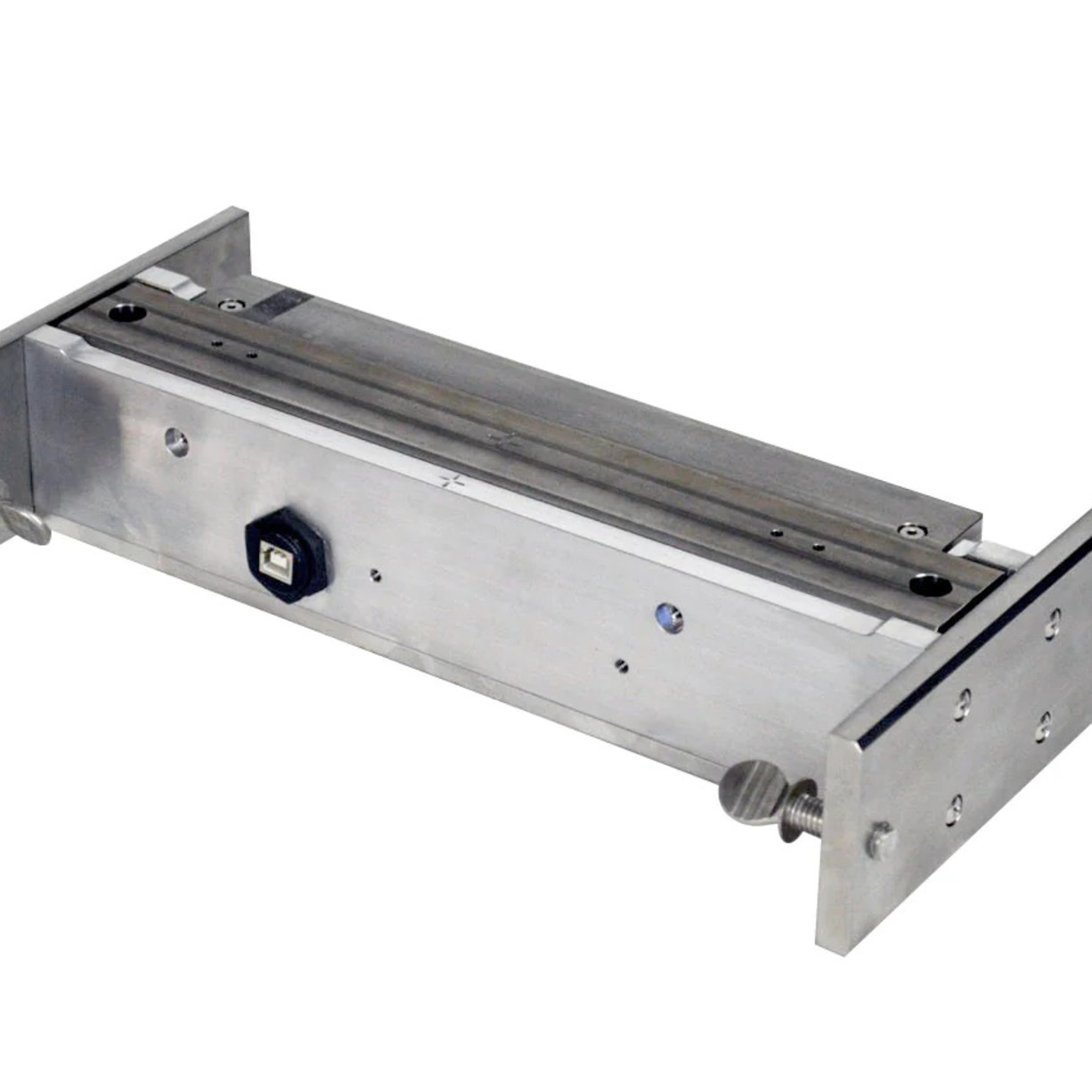

HWT-Pro™

Fast and Accurate Verification, Calibration, and Diagnostics Device for Your Hamburg Wheel Tracker

Patent No. 10,753,838

The InstroTek HWT-Pro is a comprehensive verification and diagnostic device for the Hamburg Wheel Tracker. The HWT-Pro can measure and report your machine's deviation from AASHTO T-324 calibration requirements. The HWT-Pro also follows the recommendations of NCHRP Project 20-07 Task 361 conducted at Louisiana State University. Wheel load, wheel position, wheel speed, waveform, rut depth, and water temperature can all be measured with the HWT-Pro. In addition, The HWT-Pro can detect the wheel’s position along the wheel path, its center point and measure both static and dynamic load. The dynamic wheel load is compared to a true sinusoidal wave, and the equipment's RMSE is reported. The HWT-Pro is the only device to give accurate and precise information about your Hamburg Wheel Tracker calibration.

HWT-Pro Spec PC Software

The HWT-Spec PC Software captures all data from the HTW-Pro. The software leads the user through a series of steps collecting verification data along the way. The HWT-Pro Load Sensor collects wheel load (static and dynamic), position, speed, and waveform through a USB cable, while the HWT-Pro Height Indicator provides the tools to measure LVDT displacement data safely. Three-point displacement is measured under the wheel for a more realistic displacement verification. Finally, a NIST traceable temperature indicator captures water temperature at any point along the wheel path. The HWT-Pro Verification Report provides a pass/fail summary of the Hamburg’s conformity to AASHTO T324 and graphical comparison of the wheel movement to the sinusoid wave shape.

HWT-Pro Spec Verification Report

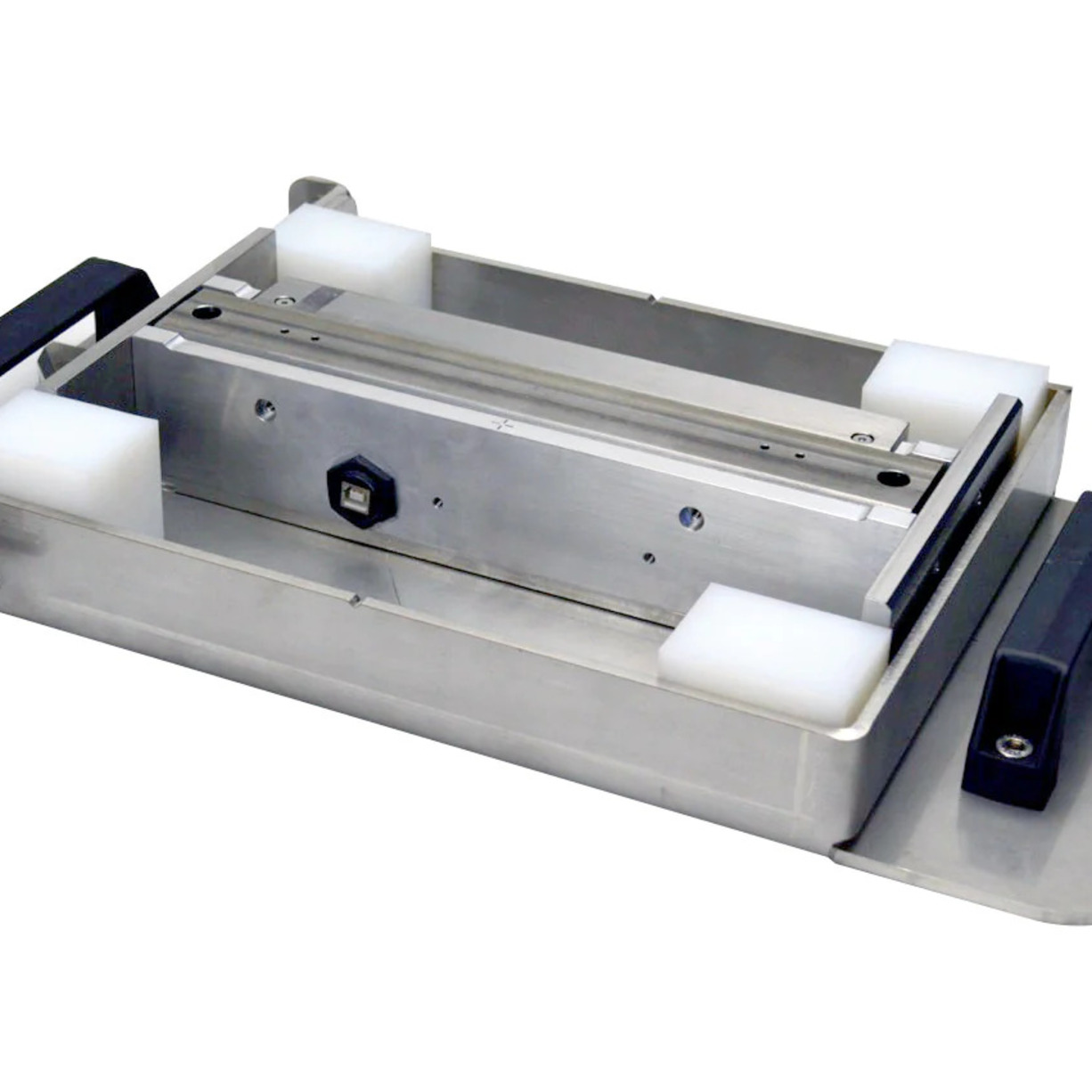

HWT-Pro Kit

The HWT-Pro consists of a carrying case, load and height verification devices, sample tray centering spacers for different model wheel trackers, NIST traceable temperature indicator, USB cable, and HWT-Spec Software. The device is made of precision machined stainless steel and quality electrical components. All measurement devices used in the HWT-Pro are NIST traceable, and the unit is provided with a calibration certificate.

The Best Diagnostic Tool for Your Hamburg Wheel Tracker

The HWT-Pro is much more than a verification tool. Equipment malfunction and non-conformance to calibration standards can often cause issues with test results. The Hamburg wheel tracker has many moving parts that can wear differently over time. Long periods of non-use before or after the construction season can cause systems to fall out of calibration. The HWT-Pro allows you to verify all calibration parameters and identify issues with your Hamburg wheel tracker that may affect test results. The HWT-Pro can track changes in performance over time and provide information that users can use to identify parts that may need replacement over the lifetime of the equipment.

- Verifies all AASHTO T-324 measurement requirements

- Meets recommendations of NCHRP Project 20-07 Task 361

- Allows for easy and safe verification of the unit, without having to place hands and fingers close to the wheel and heavy loads

- Measures wheel load, Wheel center point, waveform, displacement, and water temperature

- Measures both static and dynamic wheel load

- Checks accuracy of the wheel motion versus sinusoid and reports RMSE

- Check calibration quality before a project or after long periods of nonuse

- Quickly diagnose and troubleshoot issues with your equipment

- HWT-Spec PC Software easily captures and reports verification results

- HWP-Pro includes NIST traceability certificates

.jpg)